How Printed Circuit Board Assembly Transforms Electronic Design and Manufacturing?

How Printed Circuit Board Assembly Transforms Electronic Design and Manufacturing?

Blog Article

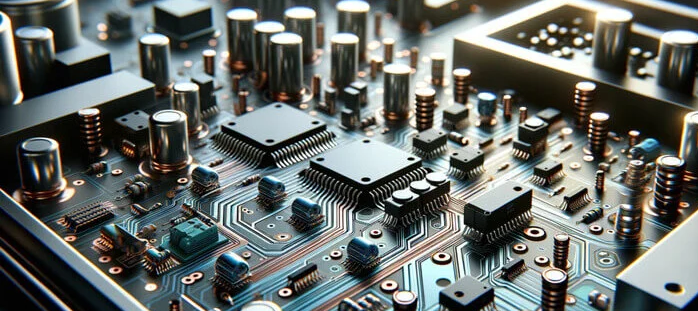

Printed Circuit Board Assembly (PCBA) plays a central part in the advancement of gadgets, empowering everything from little buyer contraptions to enormous mechanical frameworks to work productively. As innovation proceeds to progress, the integration of electronic components into useful frameworks has ended up progressively complex. PCBA serves as the spine of this integration, altogether changing both electronic plan and manufacturing forms. This change has reshaped businesses by progressing execution, lessening costs, and quickening the time to showcase for modern products.

This Content will investigate the part of PCBA in the change of electronic plan and manufacturing, analyzing its affect on circuit plan, Assembly forms, cost-efficiency, and the broader suggestions for development and worldwide supply chains.

1. Understanding Printed Circuit Board Assembly (PCBA)

A Printed Circuit Board (PCB) is the establishment for most electronic gadgets. It comprises of a lean board made from protection fabric, more often than not fibreglass or composite epoxy, with conductive pathways that interconnect different electronic components. These conductive pathways are ordinarily made of copper and permit the different components to communicate with one another.

PCBA alludes to the prepare by which electronic components are mounted onto the PCB to make a total useful electronic assembly. The components can be detached components such as resistors, capacitors, and inductors, or dynamic components like microchips, transistors, and integrated circuits (ICs). The Assembly prepare includes a few steps, counting patching, testing, and assessment to guarantee the assembly works as intended.

2. Impact of PCBA on Electronic Design

The integration of PCBA into electronic plan has changed how engineers approach the improvement of modern gadgets. Customarily, electronic plans were basic and comprised of fundamental circuitry that seem be physically collected with components put on breadboards or basic circuit boards. In any case, with the expanding request for miniaturization, complexity, and execution in advanced gadgets, the part of PCBs in plan has developed exponentially.

Miniaturization and Density

One of the most noteworthy impacts of PCBA on electronic plan is the capacity to oblige a higher thickness of components inside a littler impression. Present day electronic gadgets, from smart phones to medical implants, require progressively littler and more compact PCBs. This requests exact plan work, with components being put in ways that optimize both space and performance.

PCBA permits for the utilize of multi-layered PCBs, where a few layers of conductive fabric are stacked on best of each other, empowering more complex plans without expanding the measure of the board. This multi-layer innovation is especially critical in customer gadgets, where they require for littler, more slender gadgets is paramount.

Advanced Plan Techniques

The utilize of modern plan apparatuses such as Computer-Aided Plan (CAD) computer program has been another key improvement encouraged by PCBA. CAD program empowers engineers to demonstrate their circuit plans with awesome exactness, joining complex highlights like flag directing, control conveyance, and warm administration. These apparatuses moreover permit for re-enactments to test the plan some time recently the physical board is made, making a difference to recognize potential issues early in the process.

With PCBA, originators can moreover actualize progressed highlights like inserted components, flexible circuits, and surface-mount technology (SMT), which give more prominent usefulness and adaptability. This has given rise to advancements like flexible gadgets, wearable gadgets, and compact shopper contraptions, all of which depend intensely on the capabilities of PCBA.

Customization and Prototyping

Another significant perspective of PCBA is its part in fast prototyping. Engineers can rapidly make a model of a modern electronic plan by collecting the required components onto a PCB and testing the usefulness of the plan. This significantly diminishes the time required to bring modern items to showcase. Also, PCBA permits for customization, with the adaptability to adjust the board plan, component arrangement, or circuit arrangements in reaction to input or plan changes.

3. PCBA’s Impact on Manufacturing Efficiency

The presentation of PCBA into the manufacturing prepare has radically made strides effectiveness, speed, and adaptability. The Assembly handle for present day PCBs has ended up to a great extent robotized, diminishing they require for manual labour and human intercession, which not as it were makes strides consistency but moreover decreases the probability of errors.

Automation and Speed

Automated Assembly lines prepared with pick-and-place machines, patching robots, and assessment frameworks empower high-speed, high-precision PCB Assembly. These frameworks are competent of setting thousands of components per hour, essentially quicker than manual assembly strategies. Robotization has permitted producers to meet the tall request for hardware whereas diminishing work costs and making strides generation quality.

Cost-Effectiveness

PCBA too makes manufacturing more cost-effective. Mechanized forms lower the fetched of work and decrease fabric wastage, as components can be put with more prominent accuracy. The utilize of high-precision pick-and-place machines guarantees that components are precisely set on the PCB without harming touchy parts, which can lead to noteworthy fetched savings.

Moreover, economies of scale too come into play. As producers scale up generation, they can accomplish diminished per-unit costs for large-volume generation runs. This has made PCBA a basic portion of the gadgets supply chain, empowering companies to meet the worldwide request for customer gadgets whereas keeping costs competitive.

Quality Control and Testing

The capacity to execute exhaustive quality control measures is another critical advantage of PCBA. Mechanized testing frameworks can distinguish issues like fastening abandons, misaligned components, and electrical disappointments early in the manufacturing handle, diminishing the hazard of flawed items coming to the shopper. This upgrades item unwavering quality and client fulfilment, which are key variables in today’s competitive hardware market.

Flexible and Wearable Electronics

The flexibility of PCBA permits producers to deliver a wide run of items with changing levels of complexity, from straightforward buyer contraptions to exceedingly complex restorative gadgets. Advanced manufacturing offices are prepared with flexible generation lines that can switch between distinctive sorts of items with negligible downtime, much appreciated to the seclusion of the PCBA process.

The request for wearable gadgets such as shrewd observes, wellness trackers, and restorative checking hardware has driven to a surge in the advancement of flexible and stretchable PCBs. Conventional rigid Printed Circuit Board Assembly PCBs are being supplanted by flexible substrates that permit for circuit boards to twist and acclimate to the forms of the human body. These flexible PCBs are regularly utilized in gadgets that require lean, lightweight plans, empowering the integration of numerous capacities into compact, wearable devices.

The assembly of Flexible PCB, be that as it may, presents special challenges, such as guaranteeing legitimate component arrangement on bendable surfaces and avoiding harm to delicate components amid the assembly handle. Propels in PCBA procedures, such as the improvement of flexible patching advances and specialized materials, are making click here a difference address these challenges, clearing the way for the following era of wearable electronics.

4. The Part of PCBA in Cost Reduction

In expansion to speeding up the manufacturing handle, PCBA makes a difference diminish costs in a few ways. To begin with, it diminishes fabric costs by empowering the utilize of more cost-effective component situation advances such as Surface-Mount Technology (SMT). SMT includes mounting components straightforwardly onto the surface of the PCB, as restricted to more seasoned through-hole mounting strategies, where components are embedded through gaps and fastened to both sides of the PCB. SMT permits for littler, lighter plans, which moreover decreases fabric costs.

Second, as PCBA disposes of the require for broad manual labour in assembly, it leads to a lessening in labour costs. In locales with tall labour costs, this can altogether affect the generally taken a toll structure of electronic manufacturing.

Third, the expanded productivity and decreased mistake rates related with PCBA cruel that producers can accomplish higher yields and decrease the fetched of inadequate items. This comes about in less squander and expanded profitability.

5. The Worldwide Supply Chain and PCBA

The affect of PCBA amplifies past plan and manufacturing; it has too had significant impacts on the worldwide gadgets supply chain. PCBA empowers companies to source components and materials from all over the world, taking advantage of lower generation costs in locales such as Asia whereas keeping up tall measures of quality and precision.

The secluded nature of PCBA permits for the simple joining of diverse components, depending on territorial supply imperatives or the accessibility of specialized parts. This adaptability has made a difference cultivate the advancement of worldwide supply chains where producers can rapidly adjust to changing showcase conditions and demands.

6. Environmental Impact of PCBA

The development of PCBA has too had a critical affect on the natural impression of hardware manufacturing. The prepare itself is more energy-efficient than more seasoned, manual assembly strategies, and the utilize of SMT permits for more compact plans that expend less material.

However, there are moreover challenges. As electronic gadgets ended up progressively complex and miniaturized, the sum of squander produced, particularly in the shape of e-waste, has gotten to be a developing concern. The transfer of out of date PCBs and their components postures natural dangers, and there is expanding weight for producers to create more economical hones, such as reusing and reusing PCBs and components.

7. PCBA’s Part in Advancement and Future Technologies

The capacity of PCBA to encourage fast prototyping and productive manufacturing has driven to a wave of development in hardware. Advances such as the Internet of Things (IoT), independent vehicles, and wearable gadgets would not be conceivable without the progressions made in PCB plan and assembly.

For case, IoT gadgets depend on profoundly compact, energy-efficient PCBs that empower the integration of sensors, chip, and communication modules. Wearable gadgets like keen observes and wellness trackers require flexible, lightweight PCBs that can acclimate to the forms of the human body whereas keeping up strong performance.

Looking forward, PCBA will proceed to advance to meet the requests of rising advances such as manufactured insights (AI), quantum computing, and 5G broadcast communications. These advances will require progressively complex, high-performance PCBs, assist driving development in the PCBA industry.

8. Conclusion

Printed Circuit Board Assembly has verifiably changed the scene of electronic plan and manufacturing. By empowering miniaturization, upgrading plan capabilities, progressing manufacturing productivity, and decreasing costs, PCBA has played a key part in driving the fast headway of advanced electronics.

As the world gets to be more interconnected and innovation proceeds to advance, the part of PCBA will as it were gotten to be more critical. The capacity to rapidly plan, collect, and make electronic items with tall exactness and moo taken a toll is fundamental to assembly the developing request for imaginative gadgets and systems.

The integration of PCBA into the hardware manufacturing handle has not as it were made cutting edge gadgets more compact, productive, and dependable but has moreover encouraged a modern time of innovative headways. The continuous improvement of PCBA innovation will proceed to shape the future of gadgets, controlling the advancements that characterize tomorrow’s associated world.